Nanoscale Ultrasonic Transducers

Ultrasound is a powerful tool for diagnosing medical and mechanical problems. Conventional ultrasonics work at megahertz frequencies and with wavelengths of 1-2mms to 10’s mm. This means it cannot "see" very small objects at the nanoscale. Our new transducers are so small it is impractical to communicate with them electrically. Instead we have devised a non contact method of talking to them using short pulses of laser light.

We have adopted two approaches for producing these transducers, one method builds plates devices the other uses self assembled nanoparticles. The transducers are made from alternating metal and soft transparent layers. They have optical and mechanical resonances and so the devices have to be made such that they work well both mechanically and optically

Plate Transducers

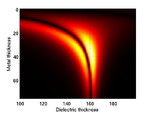

Structure is gold:ITO:gold sandwich Optical modelling shows large region of good sensitivity. Optimal device with 40 nm gold layers and 160nm ITO layer FE Mechanical model shows a main resonance at 9GHz

Devices made using standard photolithography techniques

Can be released from substrate and reattached for measurements

These transducers are 240nm high with 5- 25 micron patch sizes

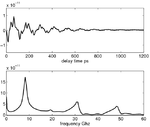

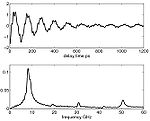

Picosecond laser ultrasound system, with locked fs lasers and electronic delay line

Pump pulse excites transducer

Probe pulse measures interaction of device with the acoustic waves

Experimental results on 10 micron patch agree very well with modelled response Weighting of harmonics differ due to slight variations in material properties and created layer sizes

Nanoparticle Transducers

Structure is gold shell around silica core Mie theory optical modelling shows repeating regions of high sensitivity 3D FEM mechanical modelling shows main breathing mode oscillation and higher order harmonics

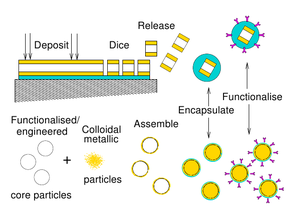

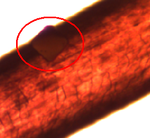

We make gold nanoparticles of the chosen shell size (10nm) Cores are made to size and functionalised with amine groups Mixing the particles together creates the final transducers The gold particles bind to the functional groups with electrostatic attraction forming a gold shell

We have made transducers with 180nm cores and 10nm shells Each batch produces trillions of transducers We need to improve the fabrication process to control the size variance to keep particles in optimal operating region Testing of these devices is ongoing

The Future

This success of this project requires the input from many different disciplines; engineering, electronics, optics, physics, pharmacy and chemistry. The devices we have made will have many potential applications e.g. chemical sensors, embedded in paints to detect the presence of specific compounds (e.g. explosives) or in the petrochemical industry for pollution and process monitoring. Biological, the transducers will be used for performing elasticity measurements inside cells to aid understanding of cell function (formation of cancers, stem cell differentiation).